3 colors Full Automatic Glass Bottle Servo System UV Screen Printing Machine With CCD positioning

Brand Name︰LC

Country of Origin︰China

Order︰1 pc

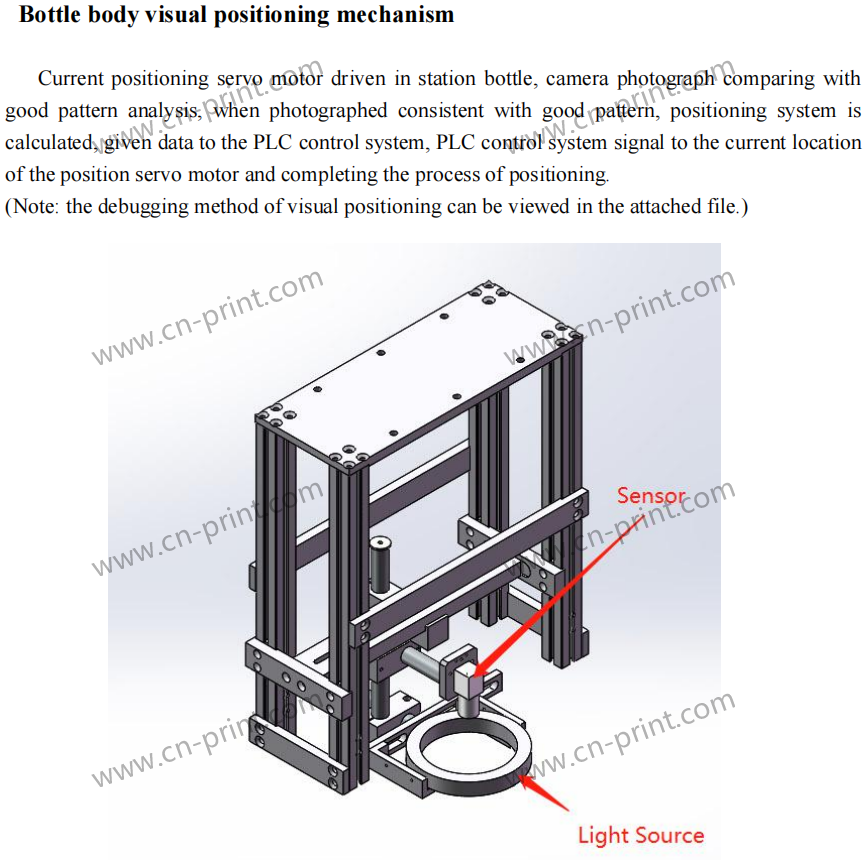

2.The visual positioning system can locate the bottle bottom or bottle body.

3.Compact look and reduced overall dimensions make it suitable for small-sized companies as well.

4.User-friendly interface which the screen can be made one turn around the machine.

5.Screen printing head can be replaced to hot stamping head,make multi color screen printing and hot stamping in one line.

|

|

|

|

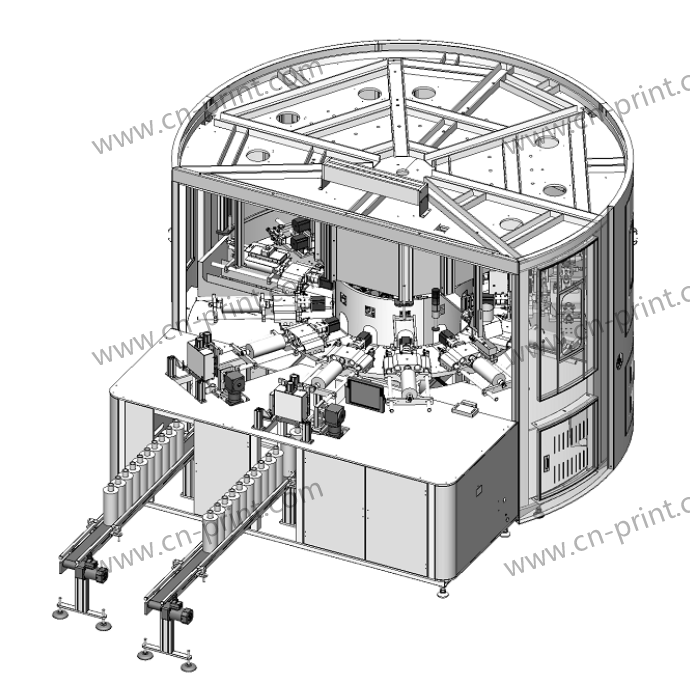

Full servo system automatic LED UV Screen printing machine

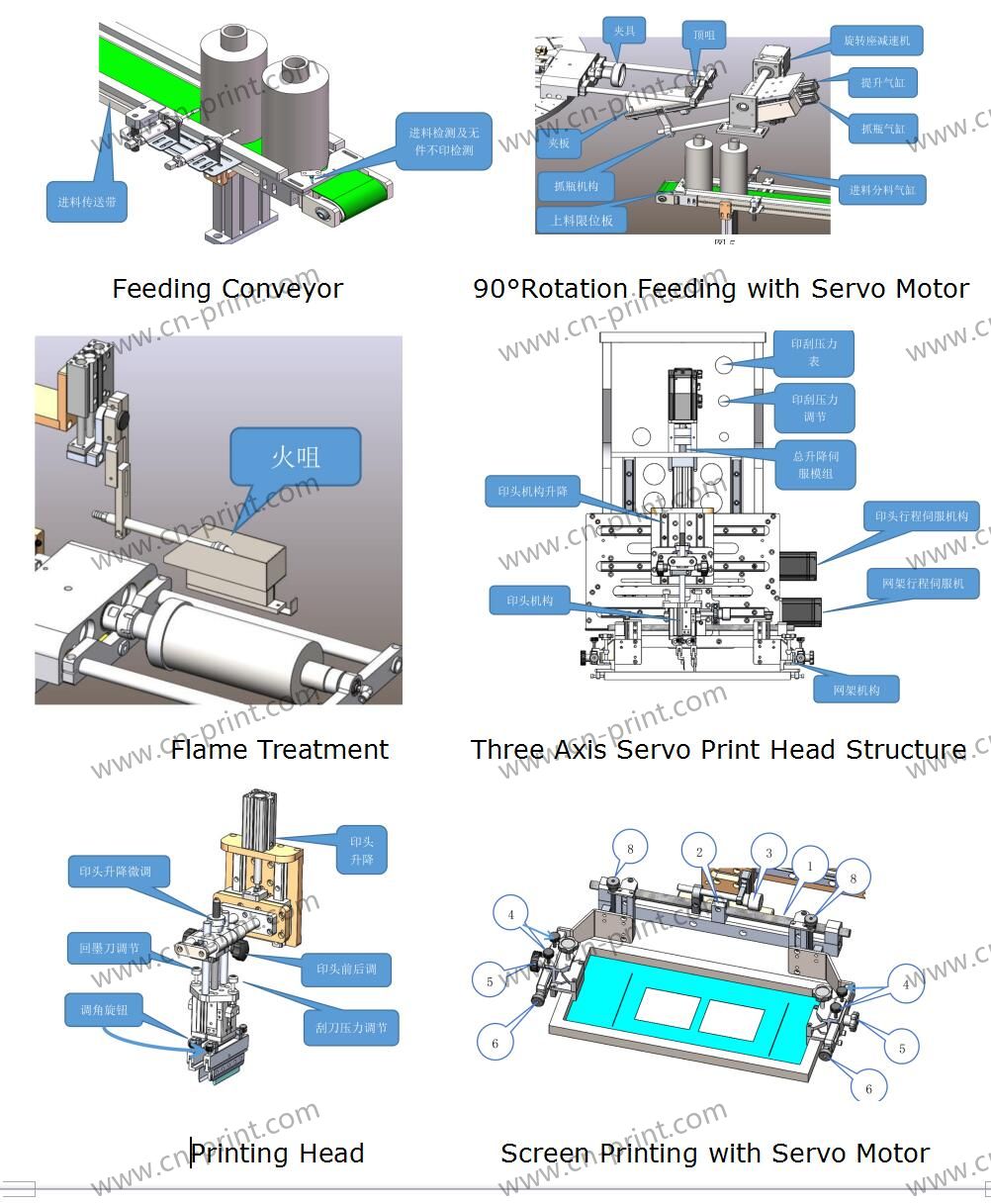

1. Auto loading with multi axis servo robot

2. The machine have two CCD system. one is line scan, other is surface scan

The bottom of the bottle is positioned by the CCD to avoid the clamping line.

Bottle body line scan vision CCD: can accurately locate the pattern and text. Can accurately avoid the parting line.

3. Dust removal and flame treatment system can be choose

Factory full servo system automatic wine glass bottle multi shape vodka champagne container LED UV screen printing machinery

1. 1#screen printing position 1. 1#screen printing position

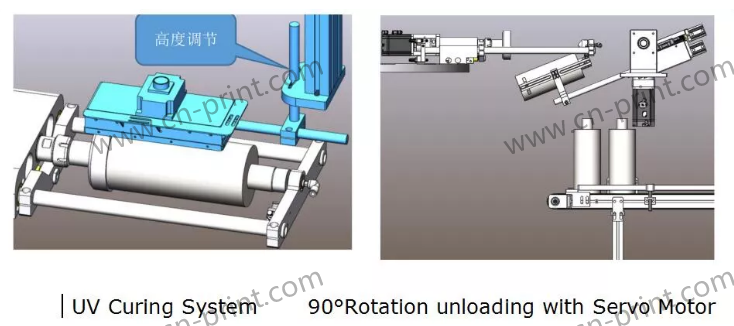

2. LED UV drying or normal UV drying (can be choose)

3. 2#screen printing position or hot foil stamping position(can be choose)

4. LED UV drying or normal UV drying (can be choose)

5. 3#screen printing position or hot foil stamping position(can be choose)

6. LED UV drying or normal UV drying (can be choose)

7.4#screen printing position or hot foil stamping position(can be choose)

8. LED UV drying or normal UV drying (can be choose)

9.unloading with multi axis servo robot

Features

2.Dust clean

3.Auto flame treatment before printing and UV LED curing after printing .

UV LED lamps and high-efficiency engines assure reduced energy consumption, Zero ozone emission and reduced CO2 production.

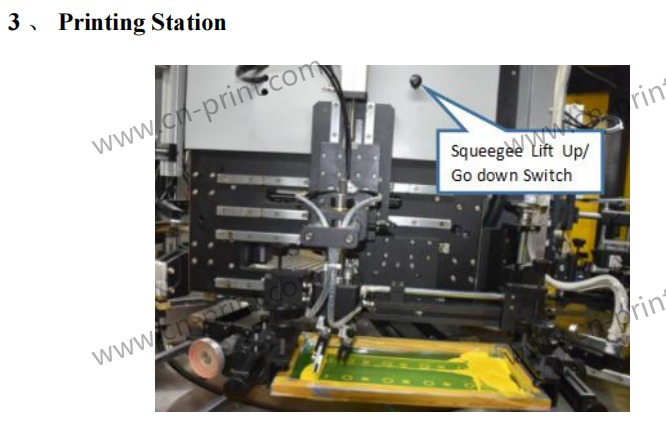

4.Auto printing system with all servo driven:printing heat ,mesh screen frame ,rotation etc.

all jigs installed with servo motors for rotation (no need gears, easy and fast products changeover)

5. Quick and easy change over from one product to another. All parameters automatic setting simply in touch screen. it only takes 20 minutes to debug each color.

6.All ethercat servo motors with industrial PLC control&touch screen operation system,internet cable connection available,easy for fucture maintenance and ungrading.

7.Adopt linear high-speed precision CCD scanning : for cylindrical products without registration point, repeat print to be double colors.

8. Well built machine house with CE standard safety design.

9.Can use UV ink or thermoplastic ink.

Specification