Automatic 4 Color Wine Bottle Screen Printing Machine With CCD Positioning

Brand Name︰LC

Country of Origin︰China

Unit Price︰-Minimum

Order︰1 pc

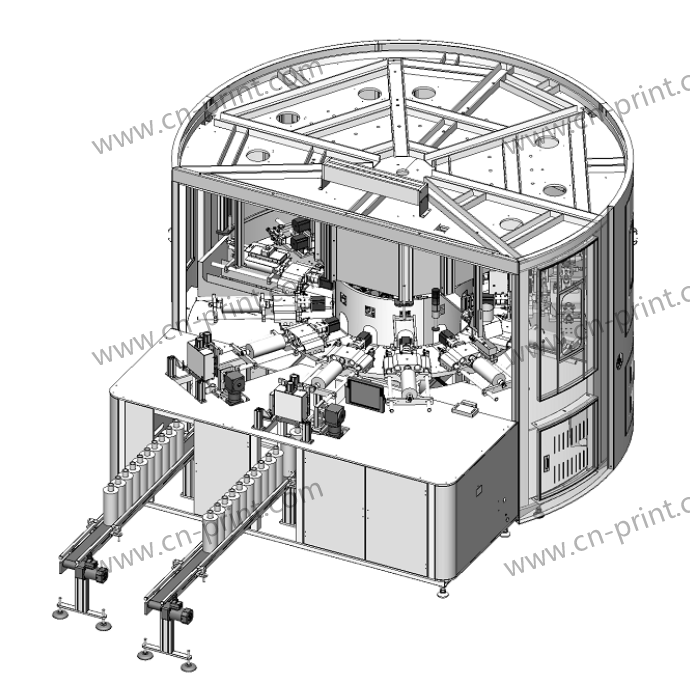

Compact look and reduced overall dimensions make it suitable for small-sized companies as well.

User-friendly interface.Screen printing head can be replaced to hot stamping head,make multi color screen printing and hot stamping in one line.

Features

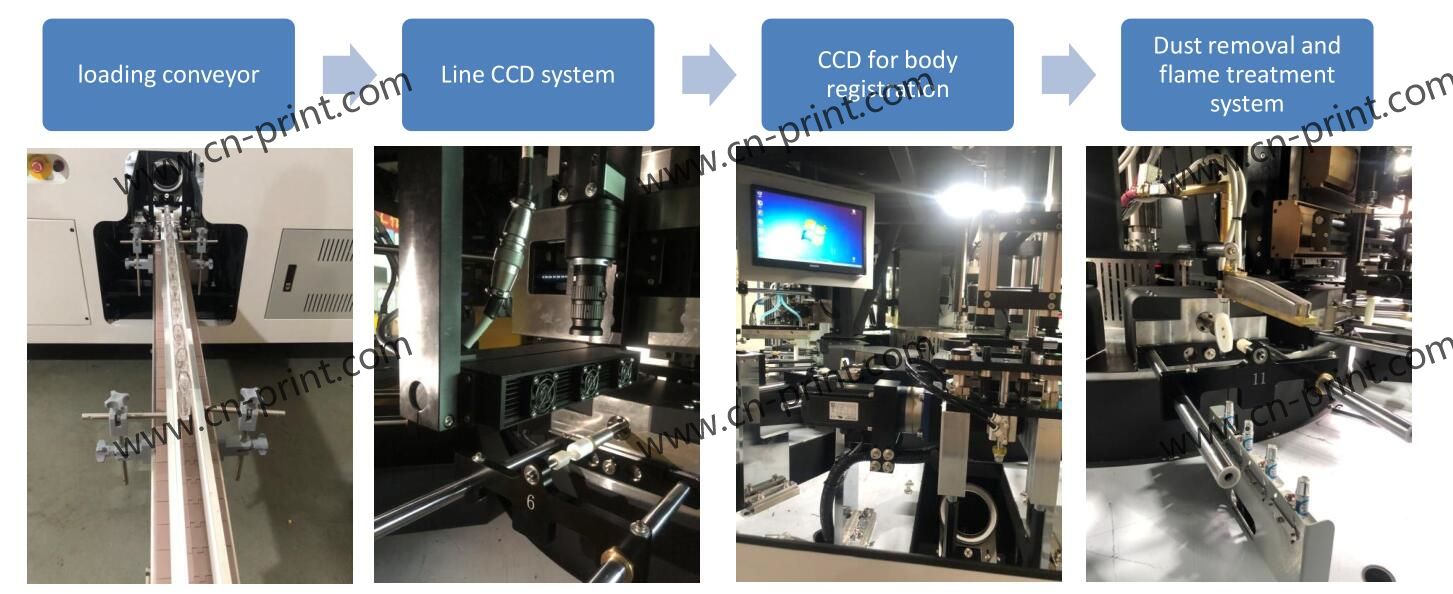

2.Dust clean

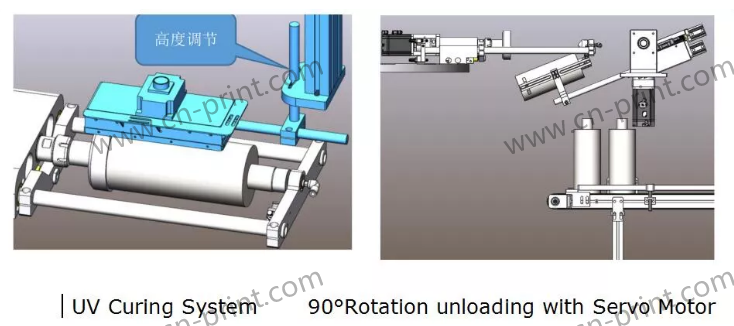

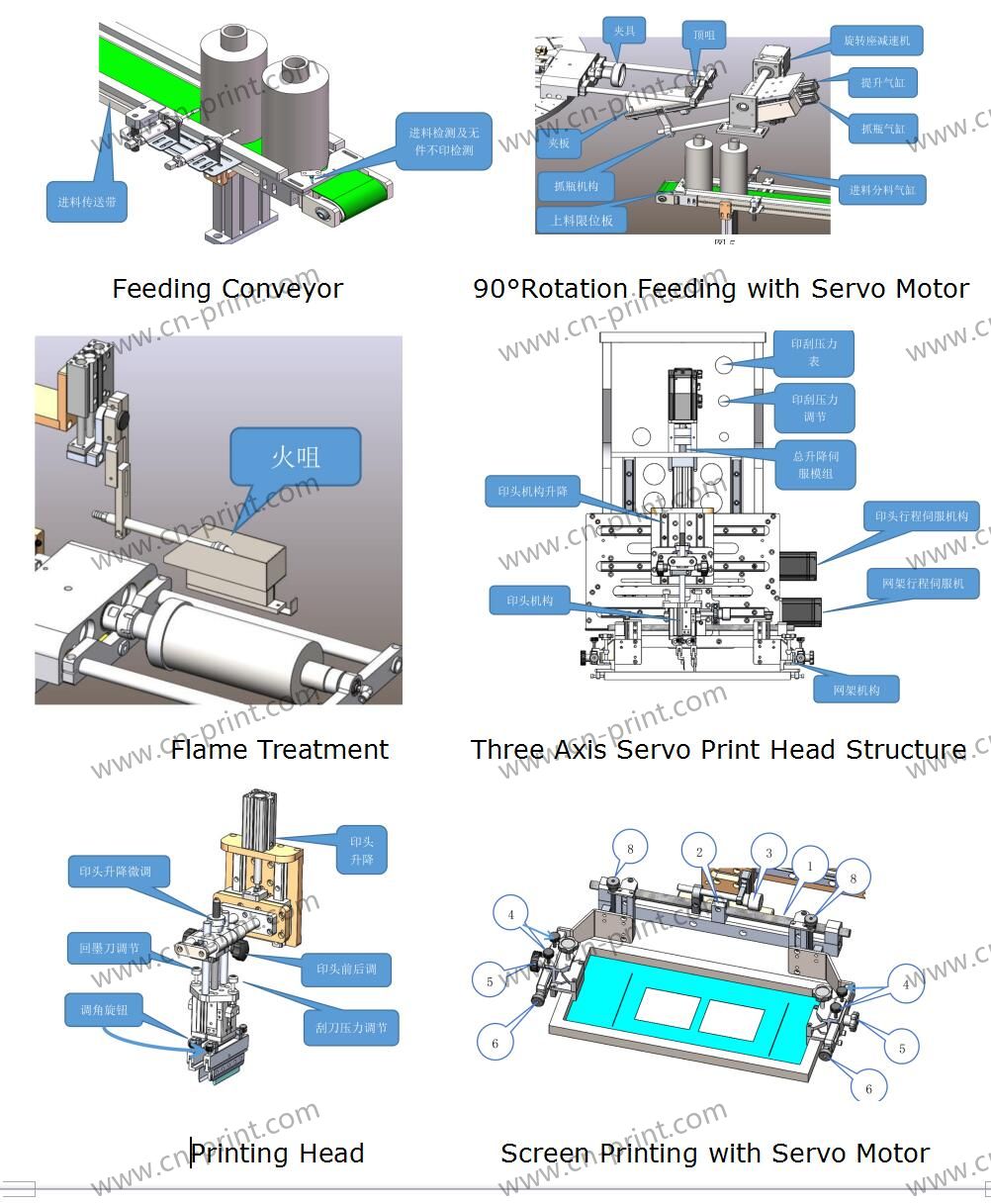

3.Auto flame treatment before printing and UV LED curing after printing .UV LED lamps and high-efficiency engines assure reduced energy consumption, Zero ozone emission and reduced CO2 production.

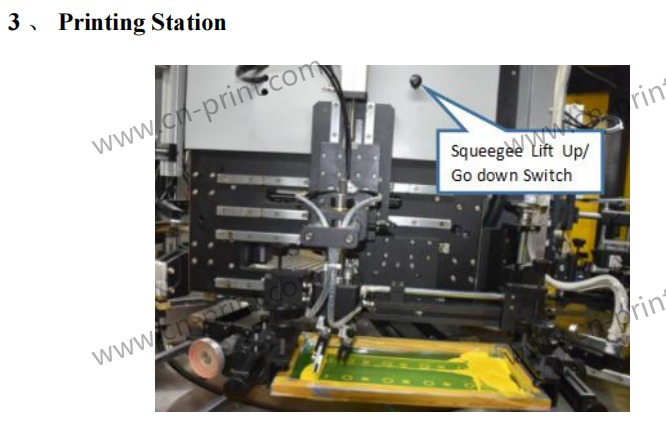

4.Auto printing system with all servo driven:printing heat ,mesh screen frame ,rotation etc.

all jigs installed with servo motors for rotation (no need gears, easy and fast products changeover)

5. Quick and easy change over from one product to another. All parameters automatic setting simply in touch screen. it only takes 20 minutes to debug each color.

6.All ethercat servo motors with industrial PLC control&touch screen operation system,internet cable connection available,easy for fucture maintenance and ungrading.

7.Adopt linear high-speed precision CCD scanning : for cylindrical products without registration point, repeat print to be double colors.

8. Well built machine house with CE standard safety design.

9.Can use UV ink or thermoplastic ink.

1、Our CNC412 weighs 5T and has a more solid frame. Additionally, each machine base has reinforcing ribs to make the machine more stable. The client feedback is that our machine is of better good quality.

2、Our machine adopts a German Beckhoff control system to ensure that data is not lost. The machine is equipped with an overall memory function, to store each parameter set for each different product. The parameter can be directly retrieved for next use, which greatly facilitates machine adjustment and greatly improves the time for converting different products, debugging the machine, and replacing fixtures. The work efficiency is greatly improved

3、 All of our electrical components are one model larger than other brand machine , including servo motors (750W, high power, strong force, stable), LED UV lights (2.5KW), solenoid valves, and guide rails.

4、Our machine's control system works smoother and more optimized programs that can withstand customer inspection.

5、 The overall servo module is in better design and better looking.

6、The servo printing head can be conveniently adjusted to scraping printing in front and back, or horizontal scraping printing in left and right directions, suitable for a wide variety of products. And front and back scraping printing function is especially suitable for printing long bottles, such as wine bottles.

7、 The heat transfer rubber roller and stamping plate could be easily interchanged. So the machine is suitable for stamping plastic and glass bottles.

Specifications

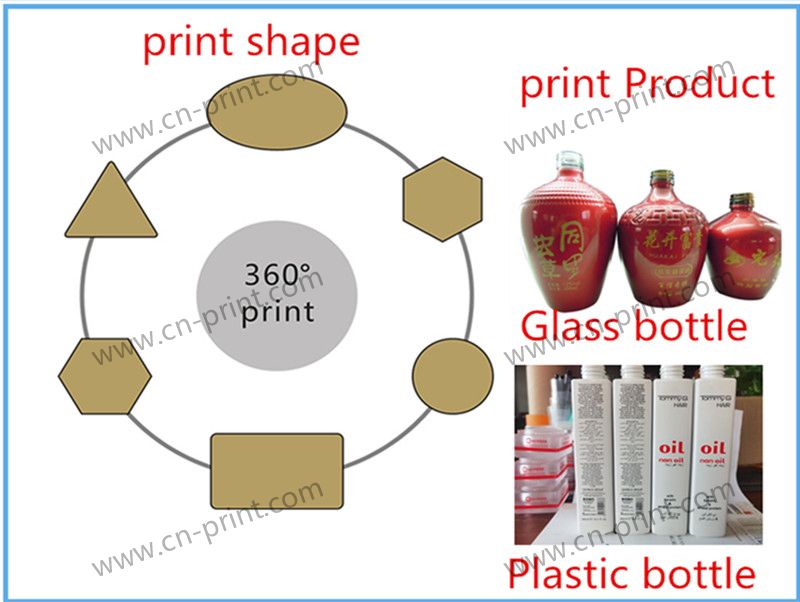

The square bottle can be printed on 4 sides at one time; the flat bottle can be printed on 2 sides at one time.

The product loading and unloading mechanism is driven by German Beckhoff + Huichuan servo drive to run more smoothly and accurately.

The screen printing fixture adopts the front and rear full clamps to ensure accurate positioning, and the screen printing process does not shake or shift;

The drive of the turntable mainly adopts the high-precision servo turntable of Spain's GOIZPER. At the same time of accurate indexing, the movement sequence of each mechanism is allocated to make the machine run more efficiently and safely.

In the process of screen printing, the lateral speed of the screen printing screen matches the speed of the circular motion of the bottle to ensure that the screen printing pattern does not stretch or shrink.

|

Model |

LC-CNC412 |

|

Printing color |

4color |

|

Printing speed |

2700-3600pcs/hr |

|

Max Product size |

round diameter 100mm, length 310mm |

|

Applicable products |

Round ,Square,Oval and other special shape glass plastic bottles,jars,cans ,cups. |

|

Left and right stroke of scraper |

355mm |

|

Scraper, oil return knife up and down stroke |

Cylinder control 20mm, adjustable screw stroke 50mm |

|

Compressed air |

5-6BAR |

|

Power supply |

380V/50HZ |

Machine Details

Printing Sample